Discover the meticulous craftsmanship behind each Laguiole en Aubrac corkscrew. From the selection of noble materials to the final polish, delve into the artisanal journey that makes these tools a symbol of French heritage and elegance.

The Legacy of Laguiole Craftsmanship

Nestled in the heart of the Aubrac region in southern France, the village of Laguiole has been synonymous with exceptional cutlery since the early 19th century. The tradition began with shepherds and farmers crafting knives suited to their daily needs, evolving over time into a hallmark of French artisanal excellence. Today, Laguiole en Aubrac continues this legacy, producing corkscrews that are not only functional but also works of art, reflecting generations of skill and dedication.

The Artisan’s Touch: A Solo Endeavor

Each Laguiole en Aubrac corkscrew is the product of a single artisan’s hands. This solitary approach ensures consistency, attention to detail, and a personal connection to the finished piece. The artisan oversees every step, from shaping the handle to assembling the mechanism, culminating in a tool that bears their unique signature, often discreetly engraved on the spring.

Selecting Noble Materials

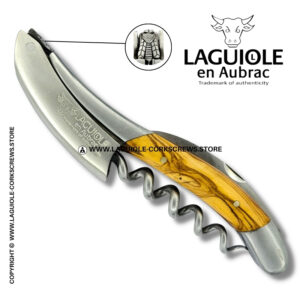

The choice of materials is paramount in the creation of a Laguiole corkscrew. Artisans select from a variety of noble materials, each bringing its own character and story:

- Woods: Olivewood, juniper, ebony, and pistachio offer distinct grains and hues.

- Horn: Buffalo and other horn materials provide durability and a unique texture.

- Bone and Ivory: Used for their smooth finish and classic appeal.

- Damascus Steel: Known for its strength and intricate patterns, often used in blades and decorative elements.

These materials are chosen not only for their aesthetic qualities but also for their ability to withstand the rigors of use, ensuring each corkscrew is both beautiful and durable.

The Step-by-Step Crafting Process

Creating a Laguiole corkscrew involves numerous meticulous steps:

- Forging the Blade and Worm: High-quality stainless steel is heated and shaped to form the foil cutter blade and the conical, grooved worm, essential for extracting corks smoothly.

- Shaping the Handle: The selected material is cut, carved, and sanded to fit comfortably in the hand, ensuring both functionality and elegance.

- Assembling the Components: The blade, worm, lever, and handle are meticulously assembled, with precise alignment to guarantee seamless operation.

- Finishing Touches: The corkscrew is polished to a satin or mirror finish, and decorative elements like chiseling or engraving are added, reflecting the artisan’s personal flair.

Signature and Certification

Upon completion, the artisan engraves their signature onto the corkscrew, a testament to its authenticity and the personal care invested in its creation. Each piece is accompanied by a certificate of authenticity, affirming its origin and the traditional methods employed in its making.

The Importance of Handcrafting

In an era dominated by mass production, the handcrafted nature of Laguiole corkscrews stands as a beacon of quality and individuality. This dedication to traditional methods ensures that each corkscrew is not only a reliable tool but also a unique piece of art, imbued with the spirit and skill of its maker.

Caring for Your Laguiole Corkscrew

To maintain the beauty and functionality of your corkscrew:

- Clean it with a soft, damp cloth after use.

- Avoid submerging it in water or placing it in a dishwasher.

- Store it in its original box or a protective case to prevent damage.

- Periodically apply a light coat of mineral oil to wooden handles to preserve their luster.

Conclusion: A Testament to Tradition

Laguiole en Aubrac corkscrews are more than mere tools; they are embodiments of a rich artisanal heritage. Each piece tells a story of dedication, skill, and the timeless appeal of handcrafted excellence. Owning one is not just about opening a bottle of wine—it’s about appreciating the artistry and tradition that make every sip more meaningful.